There’s a lot riding on today’s engineering students. The roster of challenges facing our nation and world seems as formidable as ever — updating civic infrastructure, vanquishing threats to health, creating technologies to promote the sustainability of food, energy, water and the environment.

New approaches are needed to conquer these and other challenges — and Georgia Tech is delivering. Faculty are teaching students not only how to solve problems, but also how to find and identify them; to think like designers and storytellers as well as mathematicians; to observe with curiosity and without preconceptions; to fail, get back up and try again.

The College of Engineering is a source and setting for much of this activity, and the four stories that follow illustrate how. Collectively, these stories reflect a guiding principle from the college: Meeting the world’s demands for invention requires originality and ingenuity in education.

STEM from storytelling: A teaching model comes to life

Begin with a clear jar (a mason jar will work). Add corn syrup — that’s plasma. Next, add red and white beads, the red and white blood cells. Smaller white beads are platelets. Then, shake it up.

At this stage, the fluid in the “blood jar” is sticky and viscous; or, as you might say to a group of 7-year-olds, it’s “gloopy.” So you add some water until the fluid flows naturally, providing an object lesson on why it’s important to stay hydrated.

The “blood jar” is the most popular activity devised by Dr. Wilbur Lam’s unique HealthReach class, in which biomedical engineering undergrads teach STEM concepts to hospitalized children using the kids’ illnesses as a springboard. Chronically ill children often struggle academically. They tend to miss school and combat high stress that comes with health problems. But with the hands-on experiments created by Georgia Tech students, children in Atlanta-area hospitals are enjoying their STEM lessons and often earning better grades. Lam is an associate professor in the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory.

One of Lam’s key goals with HealthReach is to teach his students how to communicate science concepts effectively to all audiences. The first semester of HealthReach is spent exploring design concepts and practicing presentations in what Lam describes as a “boot camp” for learning how to teach sick kids. Students work in groups to create activities and demonstrations like the “blood jar” and then present them to their peers in class.

Often, after developing and sharing their experiments and gadgets, students will tweak their designs. “At the core, it’s very much a design course in engineering,” Lam says. “The class enables students to really become engineers in the sense that they get to design, develop and invent and go straight to the end user, a child with a chronic disease.”

In their second semester, HealthReach students visit local Children’s Healthcare of Atlanta hospitals a couple times a week and work directly with kids. So far, they’ve interacted with about 400 student-patients, many of whom are repeat customers.

Next, Lam wants to implement a study to assess the program’s long-term impact on the academic performance of chronically ill kids. If Lam and his colleagues can produce concrete data on HealthReach’s value, it could inspire similar projects elsewhere.

Developing an entrepreneurial mindset

A young man arrives at the intensive care unit of Massachusetts General Hospital, suffering from congestion, cough, fever and chills. He is diagnosed with bronchitis, prescribed steroids, and sent home.

But a day later, he’s back in the emergency room, vomiting and struggling to breathe. The hospital admits him; doctors struggle to save him. Their efforts are unsuccessful. After two weeks, he’s removed from life support and passes away.

This case study, examined at length in the New England Journal of Medicine, forms the basis of the Engineering Physiology course taught by Kyla Ross and Phil Santangelo. Both are faculty members in the Wallace H. Coulter Department of Biomedical Engineering.

At the beginning of the course, Ross and Santangelo tell their students: “You’ve been hired by Mass General Hospital to evaluate this case. Your team is looking for missed opportunities in disease detection, progression and intervention. Your assignment is to make recommendations for a different standard of care.”

For the entire semester, students work in groups to assess this case from every conceivable angle and develop models to explain what went wrong. In the process, students synthesize and apply knowledge and techniques from many past courses.

They also draw on the considerable expertise of their professors and teaching assistants. Ross’s area is systems physiology; Santangelo’s is cell biology. Graduate assistants cover mathematical modeling and algorithm coding.

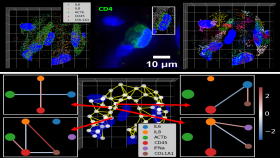

According to the final conclusions of the case study, the young man died from influenza A virus, complicated by staphylococcal pneumonia and herpes simplex virus (HSV) type II. Those complications present a number of variables. It’s up to the students to decide what problem they want to solve — and how to solve it.

One group explores how influenza’s suppression of the immune system could lead to reactivation of HSV II or accelerate staph infections; perhaps immunotherapy could have helped. Another group examines the drugs the patient received in the emergency room and modeling interactions; maybe there was an unintended immunosuppressant effect. And another group analyzes the window in which antivirals for flu would have been most effective.

Each group then analyzes their problem through mathematical models, refined through trial and error and the input of their professors and classmates. “We have them try it once, reflect on that, try it again,” Santangelo says. “The philosophy of this class is fail fast, and fail often. But it’s failure with a purpose, because the students gain the insight and competence to find and solve problems for the rest of their lives.”

Student invention from keen observation

The first-time Jorge Mena noticed a dirty ultrasound machine circulating in the emergency room, he didn’t really think about it. Someone would clean it before the next patient, right? But then he noticed the same thing again. And again.

Mena was a biomedical engineering senior, enrolled in Dr. Jeremy Ackerman’s clinical observation design course offered by the Coulter Department of Biomedical Engineering. In this class, students spend 6-8 hours a week in emergency rooms across Atlanta, and their job is to watch, listen, and learn.

Ackerman isn’t just a biomedical engineering professor; he’s also a practicing emergency physician who sees patients at some of those same Atlanta hospitals. With that interdisciplinary mindset, Ackerman challenges his students to think like designers and storytellers, and identify the hospital’s flaws in architecture, process, and technology. “We know there are problems around here somewhere,” he says. “You find them.”

For Mena, that problem was dirty ultrasound wands. A typical emergency room has just a few ultrasound machines. When a patient arrives with abdominal trauma or internal bleeding, staff grab the nearest ultrasound machine. Then, it’s on to the next patient. In the rush to save lives, there’s often no time to assemble cleaning supplies to sterilize the machine.

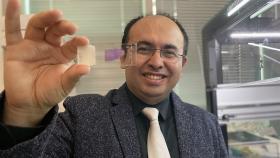

Mena observed that the ultrasound wands in use were sometimes soiled with dried gel or smears of blood, potentially exposing patients to infections. So when he began his senior design capstone project, he told his teammates about it, and together they came up with a solution: a disposable polymer pad that attaches to the ultrasound wand. One side has a slick coating that replaces the ultrasound gel. The other is adhesive so it adheres easily to the surface of the wand. After the ultrasound is performed, the technician can throw away the dirty pad.

The young entrepreneurs took their idea and launched a start-up company, SonoFAST. Today, Mena is helping to get it off the ground while also attending medical school at the University of California, San Francisco.

FlexSpark, which developed a device to prevent deep vein thrombosis, is another startup to originate from the course. Syed Hasnain, the company’s co-founder, credits Ackerman’s class with the start-up’s success. As of early 2017, the startup had raised $1.2 million in venture funding and landed a $65 million distribution contract.

“You realize, going into the corporate world, just how unprecedented this access to medical staff is,” Hasnain says. “When we began the accelerator, we were the underdogs, a bunch of undergrads competing with Ph.D.’s and working doctors. But we’d been able to get the input of about 97 different medical professionals on our device.”

This gave his team the edge, Hasnain says — and enabled them to design a device that would meet a genuine need for both patients and hospital staff.

“Most biomedical engineering courses focus on developing tools to solve problems,” Hasnain says. “But Dr. Ackerman’s course is unique in giving us the opportunity to unleash our curiosity in a practical environment and identify and solve actual problems in healthcare. It’s really a transformative experience for students who take it.”

Remaking labs for the real world

Here’s one way to practice calculating the acceleration of an object: Get a long, curved track, a pinewood derby car and a handheld accelerometer.

But the method has a few problems. For one, it’s a hassle to transport and construct such a system, so it’s very difficult to use as a classroom demo. And you can only handle one such track, which means just a few students take a hands-on role, while others have to watch.

So a Georgia Tech research group, aptly named Hands-On Learning, decided to create a replacement: a small, portable pendulum, the bottom of which holds a smart phone with a built-in accelerometer (commonplace in smart phones today).

When the pendulum starts swinging, the phone swings with it, allowing students to track and gather data about the rate of acceleration. Because the pendulum device is affordable and easy to make, every student in class gets an opportunity to work the experiment.

Hands-On Learning is one of Georgia Tech’s unique Vertically Integrated Projects or VIPs. The projects bring together interdisciplinary teams of undergraduate and graduate students, post-doc researchers and professors to tackle ambitious research challenges.

Through the Hands-On Learning VIP, undergrads earn course credit as they design better ways to explore engineering principles in the classroom. In the process, they create valuable tools and approaches to improve the learning experience for their classmates and themselves.

The group is led by Bonnie and Al Ferri, both professors and associate chairs for undergraduate affairs in their respective schools. Professor Bonnie Ferri in ECE has spent 13 years exploring ways to incorporate hands-on experiments into her electrical engineering courses. Her husband, professor Aldo Ferri, is implementing similar projects in his mechanical engineering courses.

Together, the Ferris have received three National Science Foundation grants to develop mobile hands-on experimental modules, and the experiments they’ve developed benefit about 2,500 Tech students each year.

This year, the Hands-On Learning VIP is tackling their most ambitious project yet: programming and modifying a remote-control car that rides on a customized table-top treadmill. From the car’s electronic circuitry to the mobile apps used to control it, every aspect of the project offers a way to help engineering students apply their lessons in the real world.

by Desirina Frew.

Originally published in Georgia Tech’s Engineers magazine, Spring 2017

Media Contact

Walter Rich

Keywords

Latest BME News

Commercialization program in Coulter BME announces project teams who will receive support to get their research to market.

Courses in the Wallace H. Coulter Department of Biomedical Engineering are being reformatted to incorporate AI and machine learning so students are prepared for a data-driven biotech sector.

Influenced by her mother's journey in engineering, Sriya Surapaneni hopes to inspire other young women in the field.

Coulter BME Professor Earns Tenure, Eyes Future of Innovation in Health and Medicine

The grant will fund the development of cutting-edge technology that could detect colorectal cancer through a simple breath test

The surgical support device landed Coulter BME its 4th consecutive win for the College of Engineering competition.

New research from Georgia Tech helps doctors predict how therapies will interact with a child's immune system, potentially improving outcomes and reducing risks.